循環經濟

Airesa 技術塑料材料回收的領導者

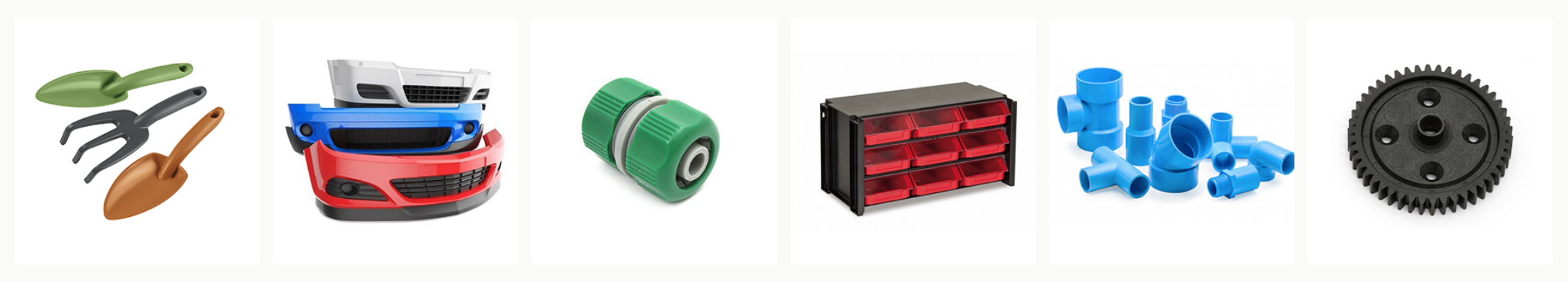

在 Airesa,我們專門從事回收塑料的買賣。憑藉我們的經驗和技術知識,我們可以為您提供量身定制的創新技術解決方案。我們是回收高性能技術材料的專家。

塑料

ABS, PC-ABS, PC (policarbonato), PVC, PET, PA (poliamida), HDPE (polietileno), LDPE, PP(polipropileno), plásticos técnicos.

我們為您提供一整套解決方案。

使用可回收包裝和回收塑料 是幫助地球的關鍵。

在 AIRESA,我們每天都致力於塑料的再利用, 以及循環和可持續經濟。

AIRESA S.L.U. has been a beneficiary of the European Regional Development Fund whose objective is to improve the competitiveness of SMEs and thanks to which it has launched an International Digital Marketing Plan with the aim of improving its online positioning in foreign markets during the year 2021. To do this has had the support of the XPANDE DIGITAL Program of the Valencia Chamber of Commerce.

PROJECT CO-FINANCED BY THE EUROPEAN REGIONAL DEVELOPMENT FUND (FEDER) THROUGH THE FEDER OPERATIONAL PROGRAM OF THE VALENCIAN COMMUNITY 2021-2027

Plastic parts classification system by volumetric inspection and articulated robots

AIRESA, S.L.U, is developing this project with file number IMDIGA/2022/313 that has been supported by the VALENCIAN INSTITUTE OF BUSINESS COMPETITIVENESS (IVACE), in its aid program for SME DIGITALIZATION PROJECTS (DIGITALIZA-CV), to the financial year 2022, and has been co-financed by the EUROPEAN REGIONAL DEVELOPMENT FUND (FEDER) in a percentage of 60% through the FEDER Operational Program of the Valencian Community 2021-2027. The objective of this project is the development, integration and testing of a solution for the inspection of volumetrics and morphology of parts through artificial vision solutions, mainly based on 3D scanning, 2D imaging and Deep Learning, for the identification of plastic parts on a belt. of transport in movement and the later identification of the same ones according to the morphology and comparing with three-dimensional models previously generated. For a correct implementation of the inspection system, the second objective of the project is to implement a primary screening by means of a vibrating system and after the inspection of the parts, two SCARA-type robotic units will be in charge of selecting the parts with very fast movements and to deposit them on different conveyor belts depending on their classification.